Expert Epoxy Flooring Preparation Services in Markham for Lasting Results

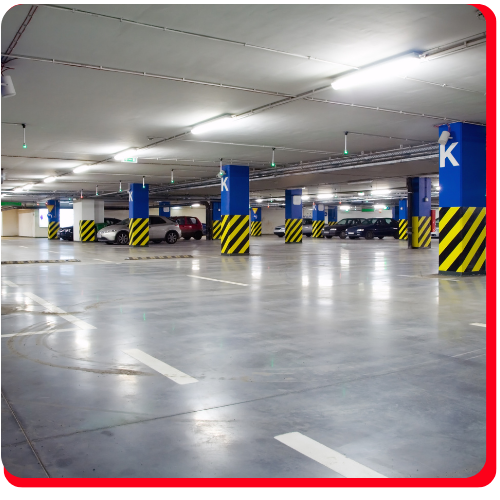

When it comes to epoxy flooring, the key to long-lasting results lies in expert preparation. At Gli Epoxy Flooring, we understand that skipping or rushing surface preparation can lead to peeling, bubbling, or uneven finishes down the line. Our team in Markham takes a meticulous approach, starting with a thorough assessment of your concrete floor to identify cracks, moisture issues, or existing coatings that need attention. Whether it’s a garage, warehouse, or commercial space at 1088 Barmac Dr, we tailor our preparation process to ensure the epoxy adheres perfectly. This initial step is what sets the foundation for a flawless, durable finish that stands up to heavy use.

One of the most critical steps in epoxy flooring preparation is surface cleaning and degreasing. Oil stains, dirt, or chemical residues can prevent the epoxy from bonding properly, leading to premature wear. Gli Epoxy Flooring uses industrial-grade cleaning solutions and equipment to deep-clean every inch of your floor, removing even the toughest grime. For garages or workshops in Markham, where oil spills are common, we pay extra attention to degreasing to eliminate any traces that could compromise adhesion. This level of detail ensures that your epoxy coating not only looks pristine but also maintains its integrity for years.

Concrete grinding is another essential part of the preparation process, especially for older or uneven floors. At Gli Epoxy Flooring, we use high-quality diamond grinders to open up the pores of the concrete, creating a rough texture that helps the epoxy grip tightly. This step is crucial for spaces like retail stores or warehouses in Markham, where heavy foot traffic or machinery can stress the flooring over time. By carefully grinding the surface, we eliminate weak spots and create a uniform base, preventing future cracks or delamination. It’s this attention to detail that makes our epoxy flooring surface preparation in Markham stand out.

Moisture testing is often overlooked but is vital for preventing epoxy failures. Excess moisture in concrete can cause bubbles or lifting, ruining your investment. Gli Epoxy Flooring uses advanced moisture meters to check your floor’s moisture levels before applying any coatings. If high moisture is detected, we implement solutions like vapor barriers or moisture mitigation systems to protect the epoxy. This proactive approach is especially important for basements or ground-level spaces in Markham, where dampness can be a recurring issue. By addressing moisture early, we ensure your epoxy floor remains flawless and functional.

Repairing cracks and imperfections is another step we take seriously at Gli Epoxy Flooring. Even small cracks can expand over time, causing the epoxy to crack along with them. Our team fills and levels any gaps using premium patching materials, creating a smooth, seamless surface. For commercial properties at 1088 Barmac Dr, where durability is a priority, this step prevents future damage and extends the life of your flooring. We don’t just cover up problems—we fix them at the root, so your epoxy floor stays strong and visually appealing for the long haul.

Priming the surface is the final touch before epoxy application, and it’s a step we never skip. A high-quality primer acts as a bonding agent, ensuring the epoxy adheres uniformly and cures properly. Gli Epoxy Flooring selects primers based on your floor’s specific needs, whether it’s enhancing adhesion for high-traffic areas or improving chemical resistance for industrial spaces. This careful selection process guarantees that your Mark

Gli Expoxy Flooring provides professional Epoxy Flooring Surface Preparation Markham services in 1088 Barmac Dr with a commitment to excellence and customer satisfaction.

Call 289-816-7049

Why Local Experience Matters for Epoxy Flooring in Markham

When it comes to epoxy flooring, local experience makes all the difference in Markham. The climate here, with its cold winters and humid summers, affects how epoxy cures and adheres to surfaces. A contractor unfamiliar with these conditions might use the wrong mix or application techniques, leading to peeling or bubbling. Gli Epoxy Flooring has years of experience working in Markham, so they know exactly how to adjust their process for optimal results. This local expertise ensures your floor not only looks great but also stands up to the region’s weather challenges.

Surface preparation is another area where local knowledge shines. Markham’s older homes and commercial spaces often have unique subfloor conditions, from concrete with moisture issues to uneven surfaces from years of wear. Gli Epoxy Flooring understands these common problems and tailors their surface preparation techniques accordingly. They might use specialized grinding methods or moisture barriers to ensure a flawless bond. Without this local insight, you could end up with a finish that fails prematurely, costing you time and money.

Local contractors also have established relationships with suppliers in the area, which can streamline your project. Gli Epoxy Flooring knows which materials perform best in Markham and can source them quickly, avoiding delays. They’re also familiar with local building codes and regulations, ensuring your flooring meets all requirements. This level of efficiency and compliance is hard to achieve with an out-of-town team that isn’t as integrated into the community.

Another advantage of hiring locally is the ability to respond quickly to any issues that arise during or after installation. If a problem occurs, Gli Epoxy Flooring can be on-site at their 1088 Barmac Dr location in no time to assess and fix it. A non-local contractor might take days or even weeks to address concerns, leaving you with an unfinished or compromised floor. Fast, reliable service is a key benefit of choosing someone who operates right in your neighborhood.

Local experience also means familiarity with the types of spaces common in Markham, from residential garages to industrial warehouses. Gli Epoxy Flooring has worked on countless projects in the area, so they understand the specific needs of each environment. For example, they know how to handle the heavy foot traffic in retail spaces or the chemical resistance required for auto shops. This tailored approach ensures your floor performs exactly as needed for your unique situation.

Word-of-mouth reputation matters in a close-knit community like Markham, and local contractors rely on it. Gli Epoxy Flooring has built trust by delivering consistent, high-quality results for homeowners and businesses alike. You can easily check their past projects or ask neighbors for feedback, something that’s harder to do with a company based outside the area. This transparency gives you peace of mind knowing you’re working with a proven professional.

Finally, supporting local businesses like Gli Epoxy Flooring strengthens the community. When you hire locally, you’re investing in Markham’s economy and fostering relationships with contractors who genuinely care about the area. Their commitment to quality isn’t just about one job—it’s about maintaining a reputation they’ve built over years of serving the community. Choosing a local expert means getting a floor that lasts and supporting the people who make your neighborhood thrive.

The National Golf Club of Canada to GLI Epoxy Flooring

Toronto Pearson International Airport to GLI Epoxy Flooring

The Step-by-Step Process Behind Our Professional Epoxy Floor Prep

At Gli Epoxy Flooring, our professional epoxy floor prep begins with a thorough assessment of your existing concrete surface. We inspect for cracks, moisture issues, and any previous coatings that could affect adhesion. This step is crucial because skipping it could lead to premature peeling or bubbling in your new epoxy floor. Our team at 1088 Barmac Dr takes the time to identify problem areas and determine the best approach for your specific flooring needs. This attention to detail ensures a flawless foundation for the epoxy application.

Once the assessment is complete, we move on to surface cleaning to remove dirt, grease, and other contaminants. Using industrial-grade equipment, we sweep, scrub, and sometimes even pressure wash the floor to eliminate stubborn grime. For garages or workshops in Markham, this step is especially important because oil spills and tire marks can interfere with epoxy bonding. Gli Epoxy Flooring uses specialized degreasers to break down tough residues, leaving your concrete perfectly prepped. A clean surface is non-negotiable for a long-lasting epoxy finish.

Next, we address any cracks or imperfections in the concrete with professional repair techniques. Small cracks are filled with high-quality epoxy or polyurethane compounds, while larger structural issues may require more extensive patching. Our team ensures every repair is smooth and level to prevent unevenness in the final coating. For businesses in Markham needing epoxy flooring surface preparation, this step prevents future cracks from telegraphing through the new epoxy layer. Proper repairs mean your floor stays pristine for years.

After repairs, we mechanically profile the surface to create the ideal texture for epoxy adhesion. Depending on the condition of your concrete, we may use diamond grinding, shot blasting, or acid etching to open up the pores of the slab. This step is critical because epoxy needs a slightly rough surface to bond securely. Gli Epoxy Flooring chooses the best method for your specific floor, ensuring maximum durability. A properly profiled floor prevents delamination and extends the life of your epoxy coating.

Moisture testing is another essential part of our prep process, especially in Markham’s variable climate. High humidity or water vapor pressure can cause epoxy to fail, so we use moisture meters and calcium chloride tests to detect hidden issues. If moisture is present, we apply a moisture barrier or vapor mitigation system before proceeding. Gli Epoxy Flooring takes no shortcuts here—proper moisture control ensures your investment stays protected. This step is particularly important for basements or ground-level spaces.

Before the epoxy is applied, we perform a final vacuuming and tack cloth wipe-down to remove all dust and debris. Even tiny particles can create imperfections, so we take extra care to ensure a spotless surface. Our team at 1088 Barmac Dr pays close attention to corners and edges where dust tends to accumulate. This meticulous approach guarantees a smooth, bubble-free epoxy application. For businesses seeking epoxy flooring surface preparation in Markham, this last prep step makes all the difference in the final result.

The final stage is priming the floor with a high-quality epoxy primer, which enhances adhesion and seals the concrete. We apply the primer evenly, making sure no spots are missed, and allow it to cure properly before the topcoat goes on. Gli Epoxy Flooring uses premium primers designed to bond tightly with both the concrete and the epoxy layers. This step not only improves durability but also enhances the color and sheen of your finished floor. With our thorough prep process, your epoxy flooring

Call 289-816-7049

Advanced Tools and Techniques for Flawless Epoxy Surface Preparation

Achieving a flawless epoxy floor starts with meticulous surface preparation, and at Gli Epoxy Flooring, we rely on advanced tools to ensure every inch is properly treated. One key technique is diamond grinding, which removes old coatings, adhesives, and uneven surfaces far more effectively than traditional sanding. This process creates a perfectly profiled surface for epoxy adhesion, preventing future peeling or bubbling. Our team at 1088 Barmac Dr uses industrial-grade grinders with diamond-embedded blades that can handle even the toughest concrete. The result is a clean, porous surface that allows the epoxy to bond securely for years to come.

Another critical step in epoxy flooring surface preparation in Markham is shot blasting, which uses high-speed steel shots to clean and texture the concrete. Unlike grinding, shot blasting is ideal for removing thin coatings or smoothing out minor imperfections without excessive dust. Gli Epoxy Flooring employs state-of-the-art shot blasting machines that adjust pressure based on surface conditions, ensuring consistent results. This method is particularly useful in commercial spaces where a uniform finish is essential. By removing contaminants and opening up the concrete’s pores, shot blasting guarantees superior epoxy adhesion.

For stubborn stains or oil contamination, Gli Epoxy Flooring utilizes specialized chemical stripping agents that break down deep-seated grime. These eco-friendly solutions penetrate the concrete without damaging its structural integrity, unlike harsh acids used in outdated methods. After application, our team at 1088 Barmac Dr employs high-pressure washing systems to flush out residues, leaving behind a pristine surface. This step is crucial in garages or industrial settings where oil and chemical spills are common. Proper chemical treatment ensures the epoxy won’t react with hidden contaminants, preserving its durability and shine.

Moisture testing is another advanced technique we prioritize before applying epoxy coatings. Excess moisture in concrete can cause epoxy to delaminate, leading to costly repairs down the line. Gli Epoxy Flooring uses digital moisture meters and calcium chloride tests to measure vapor emission rates accurately. If high moisture levels are detected, we apply moisture mitigation systems like epoxy primers designed to block vapor transmission. This attention to detail sets our epoxy flooring surface preparation in Markham apart, ensuring long-lasting results even in humid environments.

For cracks and structural flaws, Gli Epoxy Flooring employs polymer-based crack injection systems that restore the concrete’s strength. Unlike basic fillers, these advanced materials expand and contract with temperature changes, preventing future cracking. Our team carefully cleans and prepares each crack before injection, ensuring a seamless repair. This process is especially valuable for warehouses or high-traffic areas where floor integrity is critical. By addressing underlying issues before epoxy application, we eliminate weak points that could compromise the floor’s lifespan.

Dust containment is another area where advanced tools make a significant difference. Traditional grinding and blasting can spread fine particles, creating a messy and potentially hazardous work environment. Gli Epoxy Flooring uses HEPA-filtered vacuum systems attached to our grinding equipment, capturing dust at the source. This not only keeps the workspace clean but also protects nearby surfaces and improves air quality. Clients at our 1088 Barmac Dr location appreciate how this minimizes disruption, allowing businesses to resume operations faster after epoxy installation.

Finally, laser leveling ensures the prepared surface is perfectly flat before epoxy application. Even minor slopes or dips can cause pooling or uneven coating distribution, affecting both aesthetics and functionality. Gli Epoxy Flooring employs laser-guided screeding tools to

Transforming Floors in Markham with Durable, High-Performance Epoxy Coatings

When it comes to transforming floors in Markham, epoxy coatings offer a game-changing solution for both residential and commercial spaces. Unlike traditional flooring options that wear down quickly, high-performance epoxy creates a seamless, durable surface that stands up to heavy foot traffic, spills, and impacts. At Gli Epoxy Flooring, we specialize in applying these coatings with precision, ensuring a flawless finish that enhances both aesthetics and functionality. Whether it’s a garage, warehouse, or retail space, epoxy provides a sleek, modern look while delivering long-term value. Our process begins with a thorough assessment to determine the best epoxy formulation for your specific needs.

One of the standout benefits of epoxy flooring is its incredible durability, making it ideal for high-traffic areas in Markham. The coating bonds chemically with the concrete, creating a surface that resists cracks, stains, and chemical damage. For businesses like auto shops or industrial facilities, this means fewer repairs and lower maintenance costs over time. At Gli Epoxy Flooring, we use premium materials that are tested for performance, ensuring your floor can handle daily wear without losing its shine. Even in residential settings, epoxy transforms basements or garages into spaces that are both stylish and easy to clean.

Surface preparation is a critical step in achieving a flawless epoxy finish, and our team at Gli Epoxy Flooring takes this process seriously. Properly preparing the concrete ensures the coating adheres perfectly, preventing peeling or bubbling down the line. We start by cleaning, grinding, and repairing any cracks or imperfections in the existing floor at our Markham location on 1088 Barmac Dr. This meticulous approach guarantees a smooth, long-lasting result that outperforms rushed installations. Skipping this step can lead to costly fixes later, which is why we never cut corners.

Epoxy coatings aren’t just durable—they also offer endless customization options to match any design vision. From metallic finishes to flecked patterns, Gli Epoxy Flooring helps clients choose the perfect look for their space. For retail stores or showrooms, a high-gloss epoxy can brighten the area and make it more inviting, while industrial sites may prefer a slip-resistant matte finish. We work closely with customers to select colors and textures that align with their branding or personal style. The result is a floor that’s as visually striking as it is functional.

Another advantage of epoxy flooring is its resistance to moisture and chemicals, making it a smart choice for Markham’s variable climate. Basements prone to dampness or garages exposed to road salt benefit greatly from this protective barrier. At Gli Epoxy Flooring, we’ve helped countless clients safeguard their floors against water damage and harsh cleaning agents. The non-porous surface also prevents mold and mildew growth, promoting a healthier indoor environment. Whether you’re a homeowner or a business owner, this added protection can save you from costly water-related repairs.

Maintenance is a breeze with epoxy floors, which is why many Markham businesses and homeowners prefer them over traditional options. Unlike tile or hardwood, epoxy doesn’t require waxing or special cleaners—just a simple mop or sweep keeps it looking new. At Gli Epoxy Flooring, we often hear from clients who appreciate how much time they save on upkeep. Restaurants, for example, love how easily spills wipe away without leaving stains. This low-maintenance quality makes epoxy a practical investment for anyone looking to reduce long-term cleaning hassles.

Gli Expoxy Flooring provides professional Epoxy Flooring Surface Preparation Markham services in 1088 Barmac Dr with a commitment to excellence and customer satisfaction.

Call 289-816-7049How Markham’s Climate Influences the Best Epoxy Flooring Prep Methods

Markham’s climate plays a significant role in determining the best epoxy flooring prep methods, especially with its humid summers and cold winters. High humidity levels during warmer months can affect how well concrete surfaces dry before epoxy application, making moisture testing a critical step. At Gli Epoxy Flooring, we use advanced moisture meters to ensure the substrate is dry enough for proper adhesion. Skipping this step could lead to bubbling or peeling later, which is why our Epoxy Flooring Surface Preparation Markham services prioritize thorough assessments before any coating begins. Addressing these climate-specific challenges early ensures a longer-lasting finish.

Winter temperatures in Markham bring another set of challenges, as cold weather can slow down curing times for epoxy coatings. If the concrete is too cold, the epoxy may not bond correctly, leading to weak spots or uneven finishes. That’s why our team at 1088 Barmac Dr often recommends temperature-controlled environments or heating solutions for winter projects. We also adjust the epoxy mix to account for slower curing rates, ensuring the final result remains durable and seamless. Proper prep in colder months means avoiding costly repairs down the line.

Seasonal temperature fluctuations in Markham also cause concrete to expand and contract, which can create cracks or gaps over time. Before applying epoxy, our team carefully inspects the floor for any existing damage and uses specialized fillers to stabilize the surface. This step is crucial because untreated cracks can worsen under temperature changes, compromising the epoxy’s integrity. By addressing these issues during the prep phase, Gli Epoxy Flooring ensures a smooth, resilient surface that stands up to Markham’s unpredictable weather.

Rain and snowmelt in Markham can introduce excess moisture into garages and basements, where epoxy flooring is often installed. To combat this, we focus on proper drainage and sealing techniques during surface preparation. For example, applying a moisture barrier primer prevents water vapor from seeping through the concrete and affecting the epoxy bond. Our Epoxy Flooring Surface Preparation Markham services include evaluating the space for potential water exposure and tailoring solutions accordingly. This proactive approach prevents moisture-related failures, keeping floors looking pristine for years.

Markham’s spring and fall seasons bring milder weather but still require careful prep work due to fluctuating humidity levels. Epoxy coatings applied during these transitional periods need precise timing to avoid issues like condensation or improper curing. At Gli Epoxy Flooring, we monitor weather forecasts closely and schedule installations during stable conditions whenever possible. This attention to detail ensures optimal adhesion and a flawless finish, whether the project is in a residential garage or a commercial space near 1088 Barmac Dr.

Dust and debris are more prevalent in Markham during dry spells, which can interfere with epoxy adhesion if not properly managed. Our prep process includes thorough cleaning, grinding, and vacuuming to remove all contaminants from the concrete surface. Even tiny particles left behind can create imperfections, so we take extra care to achieve a dust-free base before applying any coatings. Clients who choose Gli Epoxy Flooring appreciate this meticulous approach, knowing it leads to a smoother, more professional result.

Finally, Markham’s climate demands epoxy flooring solutions that can withstand both extreme heat and freezing temperatures. That’s why we recommend high-quality, UV-resistant epoxy blends that won’t yellow or degrade under sunlight or seasonal shifts. Our team at Gli Epoxy Flooring stays updated on the latest materials and techniques to provide durable, weather-resistant finishes. Whether you’re near